Polished Concrete

Looking for a polished concrete contractor in Lexington KY or the surrounding area? Wolfcrete transforms plain concrete slabs into high-performance, visually stunning floors that stand up to heavy use and Kentucky’s changing seasons. We proudly serve residential and commercial clients throughout

Central Kentucky, including Georgetown, Frankfort, Versailles, Shelbyville, and beyond.

We understand the complexity of

a Polished Concrete floor

Not all polish concrete is equal, that's why at Wolfcrete, we pride ourselves on delivering polished concrete floors that go beyond expectations. Using cutting-edge technology and skilled craftsmanship, we produce flawless finishes that last, read on about our meticulous process and find out why we are the best at what we do.

Our Process For Stunning

Polished Concrete Floors

Here’s how we create stunning polished concrete floors for our clients in Central Kentucky

1. Surface Preparation

The process begins with thorough surface preparation, which is crucial for achieving a long-lasting finish. We start by inspecting the concrete for cracks, stains, and other surface imperfections, such as pitting or spalling. If we find any issues, we address them using top-quality patching compounds to fill in cracks and level uneven areas. Next, we perform a deep cleaning of the surface to remove dirt, oil, grease, and any other contaminants that could interfere with the chemical process of polishing. This step sets the foundation for a flawless finish and ensures the floor is ready for grinding.

2. Grinding/ Removal

Once we prepare the surface, it's time to begin the grinding phase. We gradually grind away the top layer of the concrete using industrial-grade equipment and diamond abrasives. This step removes surface imperfections and old coatings, leaving a fresh, smooth layer of concrete beneath. Depending on the desired finish and the condition of the existing floor, we adjust the depth and number of grinding passes to reveal just the right amount of aggregate. Each stage of grinding uses progressively finer abrasives, ensuring the surface is perfectly smooth and free from imperfections. By the end of this phase, the concrete is ready for the polishing process.

3. Polishing

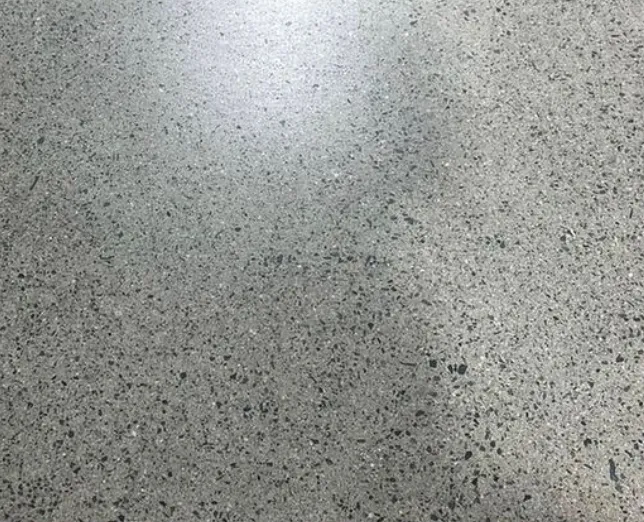

Polishing is where the true beauty of the concrete emerges. We start by honing the surface with fine diamond abrasives, refining the texture and preparing it for polishing. The honing stage brings out the natural shine of the concrete while creating a smooth, even surface. As we move through the polishing process, we use finer and finer abrasives, typically up to 3,000 grit, to achieve the desired level of gloss. Whether you prefer a soft, satin-like finish or a high-gloss mirror effect, we tailor the polishing to your specific preferences. During this stage, we may also apply a chemical densifier, which penetrates the concrete and hardens it, enhancing both durability and clarity.

4. Optional Stain Application

In this step, a stain can be applied to enhance the aesthetic appeal of the floor. Staining allows for customization, giving the surface a richer, deeper color or a completely different tone to match the design preferences. Prior to application, the floor is thoroughly cleaned and prepped to ensure even absorption. Then we apply the stain evenly across the surface, allowing it to penetrate. After the stain has fully dried, the polishing process continues, with additional layers of polish or sealant applied to protect the stain, deepen the color, and achieve a desired sheen.

5. Optional (recommended) Sealing

Sealing is an optional step that we highly recommend for most projects. While polished concrete is naturally durable, sealing adds an extra layer of protection against stains, moisture, and damage from daily wear and tear. This is especially important in high-traffic areas or spaces prone to spills, such as kitchens and garages. The sealer enhances the floor's natural color and shine, giving it an even more polished, finished look.

6. Final Burnishing & Inspection

Finally, the process concludes with a thorough burnishing and inspection. After the sealing (if applied) has cured, we perform a meticulous burnishing to enhance the shine and create a flawless, even finish. We then inspect every inch of the floor to ensure it meets our high standards of quality and craftsmanship. This last step ensures that the polished concrete floor is not only visually stunning but also durable enough to stand up to heavy foot traffic and the demands of everyday use.

COLOR OPTIONS AND FINISHES

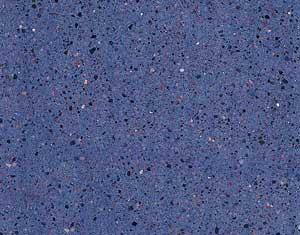

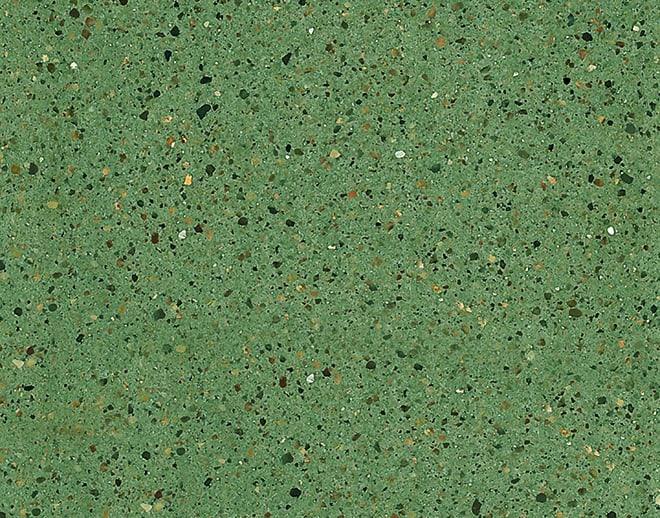

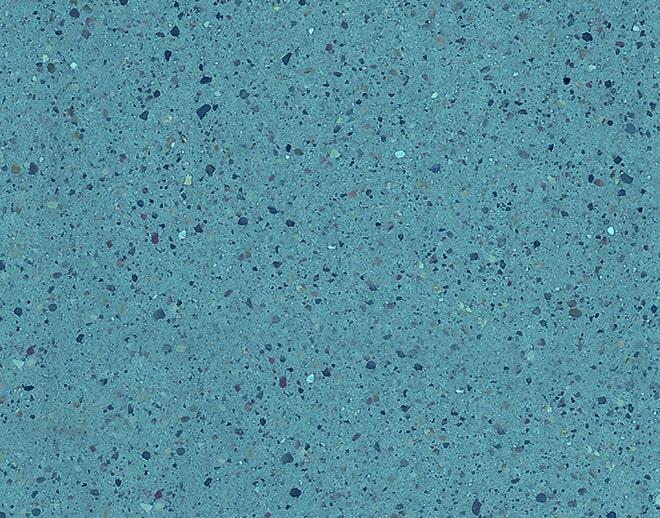

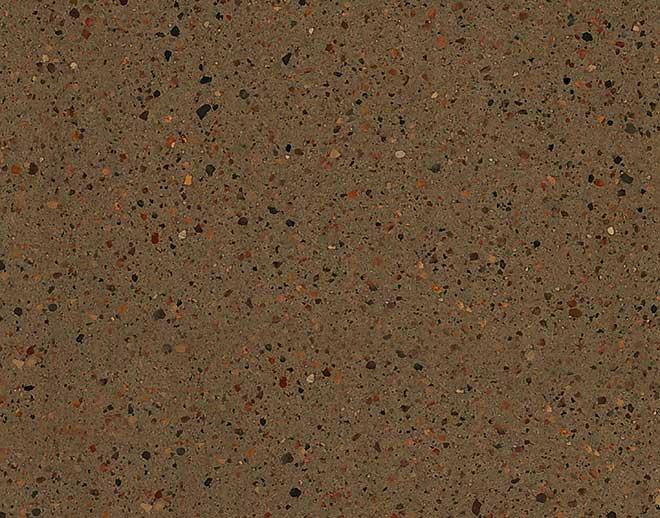

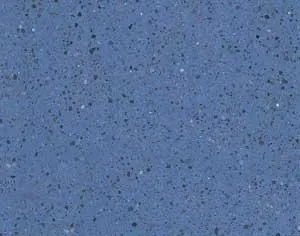

DYE COLORS

FLOOR FINISHES

A unique finish achieved on every floor

Transform your home or business with polished concrete flooring.

Wolfcrete proudly serves residential and commercial clients across Central Kentucky,

including Lawrenceburg, Lexington, Frankfort, Shelbyville, Harrodsburg, Danville, Georgetown, and Versailles.

Why Polished Concrete is perfect for your next project in Central Kentucky

Durable and Customizable

Flooring for Every Space

Polished concrete has become a go-to flooring option across Central Kentucky—for good reason. With the region's mix of hot, humid summers and cold, damp winters, you need a surface that can handle drastic temperature shifts, moisture, and heavy foot traffic without breaking down. Polished concrete offers just that. Its dense, sealed surface resists moisture intrusion, staining, and abrasion, making it perfect for everything from basements and garages to showrooms and storefronts.

Durability: Built to last, polished concrete floors withstand high foot traffic, moisture, and drastic temperature shifts.

Low Maintenance: Easy to clean and maintain, polished concrete is perfect for both busy homes and commercial environments.

Cost-Effective: Save on long-term maintenance with floors that require little upkeep and last for decades.

Eco-Friendly: By utilizing existing concrete surfaces, polished concrete reduces the need for new materials, making it a sustainable option.

Stylish & Modern: Achieve a high-end look that complements natural and contemporary aesthetics.

The Wolfcrete Difference

At Wolfcrete, we understand how daunting it can be to find a trustworthy, fairly priced flooring contractor. The horror stories are all too common—people hiring inexperienced crews or handymen promising quick, cheap fixes, only to vanish after the payment clears, leaving behind floors that fail to hold up. That's not the way we do business.

Flooring isn’t just a side gig for us—it’s our passion, our expertise, and our focus. Whether you're dreaming of a sleek polished concrete floor for your home, need industrial-strength epoxy flooring for your warehouse, or want a durable coating for a high-traffic area, our knowledge and craftsmanship are unmatched. We don’t just dabble in flooring; we are committed to the craft, bringing years of experience and a drive for excellence to every project.

Fully insured for your peace of mind and proudly serving the Central Kentucky region, including Lawrenceburg, Lexington, Frankfort, Shelbyville, Harrodsburg, Danville, Georgetown, and Versailles.

Craftsmanship You Can Count On

From residential garages to large commercial spaces, we’ve seen it all and mastered it all. At Wolfcrete, we specialize in transforming spaces with precision and care, using only the best materials designed for durability and longevity. Our experience not only ensures projects are completed on time, but also that they’re done right—the first time.

A great floor starts with a solid foundation, and that means proper surface preparation. We don’t just throw on an epoxy coating or polish the concrete; we meticulously prepare every substrate, ensuring a flawless finish that will stand the test of time. Whether it’s a patio, a commercial kitchen, or even a large industrial hangar, we treat each project with the same dedication and attention to detail.

Quality You Deserve, Without Compromise

We believe in delivering top-quality flooring solutions without unnecessary upsells or inflated costs. From the moment we begin working with you, our pricing is straightforward—no hidden fees, no surprises. We’ve built our business on trust and repeat customers, and we take that commitment seriously.

When you choose Wolfcrete, you're not just hiring a contractor—you’re gaining a partner in your flooring journey. From the first conversation to the final walk-through, we make the entire process seamless and stress-free. Whether it’s a gleaming polished concrete floor or a resilient epoxy coating ready to handle heavy traffic, we ensure the end result leaves you more than satisfied. With Wolfcrete, you get the peace of mind that comes from working with a team that truly cares about delivering excellence.

WOLFCRETE

Leading the Pack in Decorative Concrete Solutions

At Wolfcrete, we understand how daunting it can be to find a trustworthy, fairly priced flooring contractor. The horror stories are all too common—people hiring inexperienced crews or handymen promising quick, cheap fixes, only to vanish after the payment clears, leaving behind floors that fail to hold up. That's not the way we do business.

Flooring isn’t just a side gig for us—it’s our passion, our expertise, and our focus. Whether you're dreaming of a sleek polished concrete floor for your home, need industrial-strength epoxy flooring for your warehouse, or want a durable coating for a high-traffic area, our knowledge and craftsmanship are unmatched. We don’t just dabble in flooring; we are committed to the craft, bringing years of experience and a drive for excellence to every project.

Fully insured for your peace of mind and proudly serve the Central Kentucky region, including Lawrenceburg, Lexington, Frankfort, Shelbyville, Harrodsburg, Danville, Georgetown, and Versailles.

Craftsmanship You Can Count On

From residential garages to large commercial spaces, we’ve seen it all and mastered it all. At Wolfcrete, we specialize in transforming spaces with precision and care, using only the best materials designed for durability and longevity. Our experience not only ensures projects are completed on time, but also that they’re done right—the first time.

A great floor starts with a solid foundation, and that means proper surface preparation. We don’t just throw on an epoxy coating or polish the concrete; we meticulously prepare every substrate, ensuring a flawless finish that will stand the test of time. Whether it’s a patio, a commercial kitchen, or even a large industrial hangar, we treat each project with the same dedication and attention to detail.

Quality You Deserve, Without Compromise

We believe in delivering top-quality flooring solutions without unnecessary upsells or inflated costs. From the moment we begin working with you, our pricing is straightforward—no hidden fees, no surprises. We’ve built our business on trust and repeat customers, and we take that commitment seriously.

When you choose Wolfcrete, you're not just hiring a contractor—you’re gaining a partner in your flooring journey. From the first conversation to the final walk-through, we make the entire process seamless and stress-free. Whether it’s a gleaming polished concrete floor or a resilient epoxy coating ready to handle heavy traffic, we ensure the end result leaves you more than satisfied. With Wolfcrete, you get the peace of mind that comes from working with a team that truly cares about delivering excellence.

Polished Concrete

Frequently Asked Questions

Have a question that isn't answered on our site? Write us in the chat!

What is polished concrete?

Polished concrete is a multi-step process where an existing concrete surface is ground down using industrial-grade machinery fitted with diamond polishing pads. These pads gradually smooth the surface, moving from coarse grit to finer ones, until the concrete achieves a glossy, reflective finish. Beyond aesthetics, polished concrete enhances durability, abrasion resistance, and stain resistance, making it both a visually appealing and practical flooring solution for residential and commercial spaces.

Why is polished concrete a great choice for my upcoming project?

Polished concrete is particularly well-suited for the climate in Central Kentucky, because of its resilience against moisture and temperature fluctuations. With experiencing both wet winters and warm summers, polished concrete holds up exceptionally well, resisting water damage and maintaining its structural integrity. It's also naturally energy-efficient—its thermal mass helps regulate indoor temperatures, keeping spaces cooler in the summer and warmer in the winter, which can be particularly beneficial in the fluctuating weather conditions of Central Kentucky.

Can polished concrete be used outdoors?

Yes, polished concrete can be used in outdoor settings such as patios, driveways, and walkways. However, for outdoor applications, it’s important to adjust the finish to avoid excessive slipperiness when wet. Polished concrete’s durability makes it an ideal choice for exterior spaces in Central Kentucky, where the climate brings a mix of hot, humid summers and cold, wet winters. With proper sealing, polished concrete resists moisture penetration, helping prevent damage from the freeze-thaw cycles that are common during Kentucky’s colder months. Its resilience against rain, snow, and fluctuating temperatures makes it a long-lasting and low-maintenance solution for outdoor surfaces.

How much maintenance does polished concrete require?

Polished concrete is very low-maintenance compared to other flooring options. To keep the surface looking its best, regular dust mopping or sweeping is recommended to remove dirt and debris that can cause abrasion. Periodically, you can clean the floor with a damp mop using a pH-neutral cleaner. Unlike wood or tile, polished concrete does not require waxing or sealing over time, significantly reducing upkeep. For high-traffic areas, a light polishing every few years may be recommended to restore the original sheen, but overall maintenance is minimal.

How does polished concrete perform in high-traffic areas?

Polished concrete excels in high-traffic environments, making it a preferred choice for commercial spaces like warehouses, retail stores, and office buildings, as well as busy residential spaces like hallways and garages. The hardening compounds used during the polishing process make the surface extremely tough, allowing it to resist scratches, scuffs, and abrasions that would damage other flooring materials. Even after years of heavy use, polished concrete retains its smooth, glossy appearance with minimal wear.

Can I use polished concrete in my home?

Absolutely! Polished concrete is a fantastic option for residential homes in Central Kentucky. Its modern, minimalist aesthetic makes it popular for open-concept living areas, kitchens, and basements. The natural finish of polished concrete can complement a variety of interior styles, from contemporary to industrial. It’s also highly practical in homes with pets or children, as it’s resistant to stains, scratches, and allergens. Additionally, polished concrete can be heated with in-floor radiant heating systems, offering a cozy, energy-efficient solution for colder months.

What is the installation process for polished concrete?

The polished concrete process starts with surface preparation, where any cracks, chips, or imperfections in the concrete slab are repaired. Then, the surface is mechanically ground with coarse diamond pads to remove any existing coatings or debris. The grinding process continues with progressively finer pads, honing the surface and removing imperfections. Once the desired smoothness is achieved, a chemical densifier is applied to harden the concrete, increasing its durability. Finally, the surface is polished to the desired sheen, from matte to high-gloss. Wolfcrete follows strict quality control at every step to ensure a flawless, long-lasting floor.

How long does it take to install polished concrete?

The timeline for polished concrete installation depends on factors like the size of the space, the condition of the existing slab, and the desired finish. For an average residential project, the process can take anywhere from 3 to 7 days, while larger commercial spaces may take longer. If the concrete slab requires significant repair or preparation, that could also extend the timeline. Wolfcrete will provide a detailed project schedule to ensure the installation process runs smoothly.

How does polished concrete compare in cost to other flooring options?

While the upfront cost of polished concrete may be comparable to or slightly higher than materials like tile or carpet, its long-term value makes it an economical choice. Polished concrete’s durability and low maintenance mean that you won’t have to worry about frequent repairs, replacements, or expensive upkeep. In commercial settings, the ease of cleaning and the extended lifespan provide significant cost savings over time.

Why choose Wolfcrete to do my polished concrete floors ?

Wolfcrete is the premier choice for polished concrete in Central Kentucky, because of our dedication to quality, craftsmanship, and customer satisfaction. With years of experience in the flooring industry, we understand the unique challenges of working with concrete in Central Kentucky's climate. Whether it's a residential garage, a commercial showroom, or an industrial warehouse, our team approaches every project with the same level of precision and care.

We take the time to assess the condition of your existing concrete, ensuring it’s properly prepared for polishing to guarantee a flawless and long-lasting finish. Using industry-leading equipment and materials, we deliver polished concrete floors that are not only beautiful but also built to withstand the test of time, even in high-traffic or heavy-use environments. Our transparent pricing means you’ll never face hidden fees or unnecessary upsells—just honest, reliable service.

From consultation to completion, we pride ourselves on clear communication and a seamless process. When you choose Wolfcrete, you’re not just getting a flooring contractor—you’re partnering with a team of professionals dedicated to transforming your space and exceeding your expectations.

OUR SERVICES

OUR SERVICES

OUR SERVICES

Serving Lexington and Surrounding Communities

While we're based in Lexington, our polished concrete services extend throughout Central Kentucky, including Frankfort, Danville, Lawrenceburg, Harrodsburg, Shelbyville, Georgetown, and more. Whether it’s a residential basement or a high-traffic commercial floor,

we bring the same quality and care to every job, no matter the ZIP code.

CONTACT US TODAY

Frequently Asked Questions

Have a question that isn't answered on our site? Write us in the chat!

What is polished concrete?

Polished concrete is a multi-step process where an existing concrete surface is ground down using industrial-grade machinery fitted with diamond polishing pads. These pads gradually smooth the surface, moving from coarse grit to finer ones, until the concrete achieves a glossy, reflective finish. Beyond aesthetics, polished concrete enhances durability, abrasion resistance, and stain resistance, making it both a visually appealing and practical flooring solution for residential and commercial spaces.

Why is polished concrete a great choice for my upcoming project?

Polished concrete is particularly well-suited for the climate in Central Kentucky, because of its resilience against moisture and temperature fluctuations. With experiencing both wet winters and warm summers, polished concrete holds up exceptionally well, resisting water damage and maintaining its structural integrity. It's also naturally energy-efficient—its thermal mass helps regulate indoor temperatures, keeping spaces cooler in the summer and warmer in the winter, which can be particularly beneficial in the fluctuating weather conditions of Central Kentucky.

How long does polished concrete last?

Polished concrete is known for its longevity, often lasting 20 to 30 years or more with minimal maintenance. Its lifespan far exceeds that of other flooring materials like carpet or vinyl, which may need replacing every 5 to 10 years. Because polished concrete involves hardening and densifying the surface, it is highly resistant to wear, even in high-traffic areas. The durability of polished concrete makes it a great investment for both homeowners and businesses looking for a long-term flooring solution.

Is polished concrete slippery?

Although polished concrete has a high-gloss finish, it is not typically slippery when dry. The polishing process does not create a smooth surface in the same way that tile or glass might, and many polished concrete floors actually have a degree of traction. For areas where slip resistance is crucial, such as kitchens or entryways, Wolfcrete can apply specialized anti-slip coatings or finishes that ensure safety without compromising the aesthetic appeal.

Can polished concrete be used outdoors?

Yes, polished concrete can be used in outdoor settings such as patios, driveways, and walkways. However, for outdoor applications, it’s important to adjust the finish to avoid excessive slipperiness when wet. Polished concrete’s durability makes it an ideal choice for exterior spaces in Central Kentucky, where the climate brings a mix of hot, humid summers and cold, wet winters. With proper sealing, polished concrete resists moisture penetration, helping prevent damage from the freeze-thaw cycles that are common during Kentucky’s colder months. Its resilience against rain, snow, and fluctuating temperatures makes it a long-lasting and low-maintenance solution for outdoor surfaces.

How much maintenance does polished concrete require?

Polished concrete is very low-maintenance compared to other flooring options. To keep the surface looking its best, regular dust mopping or sweeping is recommended to remove dirt and debris that can cause abrasion. Periodically, you can clean the floor with a damp mop using a pH-neutral cleaner. Unlike wood or tile, polished concrete does not require waxing or sealing over time, significantly reducing upkeep. For high-traffic areas, a light polishing every few years may be recommended to restore the original sheen, but overall maintenance is minimal.

Can I customize the color of my polished concrete floor?

Yes, polished concrete is highly customizable. Wolfcrete offers the option to apply concrete stains or dyes during the polishing process, allowing you to achieve virtually any color you desire. From earth tones that enhance the natural look of concrete to bold, vibrant colors for more artistic or commercial spaces, the customization possibilities are vast. Stains and dyes penetrate the concrete surface, creating long-lasting color that won’t chip or peel like traditional flooring coatings. Check out the variety of colors that we have to offer!

Is polished concrete eco-friendly?

Polished concrete is one of the most environmentally friendly flooring options available. Since it utilizes the existing concrete slab, there’s no need for additional materials like wood, tile, or carpet. This reduces waste and minimizes the environmental impact associated with manufacturing, shipping, and disposing of other flooring materials. Additionally, polished concrete’s durability means fewer replacements over time, and its light-reflective surface can help reduce energy usage by improving indoor lighting conditions, particularly in large commercial spaces.

How does polished concrete perform in high-traffic areas?

Polished concrete excels in high-traffic environments, making it a preferred choice for commercial spaces like warehouses, retail stores, and office buildings, as well as busy residential spaces like hallways and garages. The hardening compounds used during the polishing process make the surface extremely tough, allowing it to resist scratches, scuffs, and abrasions that would damage other flooring materials. Even after years of heavy use, polished concrete retains its smooth, glossy appearance with minimal wear.

Can I use polished concrete in my home?

Absolutely! Polished concrete is a fantastic option for residential homes in Central Kentucky. Its modern, minimalist aesthetic makes it popular for open-concept living areas, kitchens, and basements. The natural finish of polished concrete can complement a variety of interior styles, from contemporary to industrial. It’s also highly practical in homes with pets or children, as it’s resistant to stains, scratches, and allergens. Additionally, polished concrete can be heated with in-floor radiant heating systems, offering a cozy, energy-efficient solution for colder months.

What is the installation process for polished concrete?

The polished concrete process starts with surface preparation, where any cracks, chips, or imperfections in the concrete slab are repaired. Then, the surface is mechanically ground with coarse diamond pads to remove any existing coatings or debris. The grinding process continues with progressively finer pads, honing the surface and removing imperfections. Once the desired smoothness is achieved, a chemical densifier is applied to harden the concrete, increasing its durability. Finally, the surface is polished to the desired sheen, from matte to high-gloss. Wolfcrete follows strict quality control at every step to ensure a flawless, long-lasting floor.

How long does it take to install polished concrete?

The timeline for polished concrete installation depends on factors like the size of the space, the condition of the existing slab, and the desired finish. For an average residential project, the process can take anywhere from 3 to 7 days, while larger commercial spaces may take longer. If the concrete slab requires significant repair or preparation, that could also extend the timeline. Wolfcrete will provide a detailed project schedule to ensure the installation process runs smoothly.

Is polished concrete resistant to stains?

Polished concrete is highly resistant to stains because of its dense, non-porous surface. The chemical densifiers used during the polishing process close off the concrete’s pores, making it difficult for liquids like oil, wine, or chemicals to penetrate the surface. However, for areas prone to frequent spills, like kitchens or garages, applying an additional sealant can provide even greater stain resistance, offering peace of mind and easier cleanup.

Will polished concrete crack over time?

Polished concrete itself does not crack, but like any concrete surface, it may develop cracks due to settling or shifting in the underlying substrate. Wolfcrete mitigates this risk by thoroughly inspecting and preparing the existing concrete before polishing. Any minor cracks are filled and patched during the polishing process, and expansion joints can be incorporated to accommodate natural movement, reducing the likelihood of future cracks.

Can polished concrete be heated?

Yes, polished concrete is an excellent candidate for in-floor radiant heating systems. Concrete’s natural thermal mass allows it to absorb and retain heat efficiently, making it a comfortable and energy-efficient option during Kentucky's winters. Radiant heating not only keeps the floors warm underfoot but also helps regulate the overall temperature of your home or commercial space, reducing the need for traditional heating methods.

Is polished concrete a suitable choice for people with allergies?

Polished concrete is an ideal flooring choice for people with allergies because it doesn’t trap dust, pollen, or pet dander like carpet or some types of wood flooring can. Its smooth, sealed surface makes it easy to clean and maintain a dust-free environment, reducing common allergens in the home. Additionally, polished concrete does not require chemical adhesives or finishes, making it a healthier option for indoor air quality.

Can polished concrete be repaired if damaged?

Yes, polished concrete can be repaired if it becomes damaged. Minor cracks, chips, or surface wear can be patched and polished back to their original condition. Wolfcrete specializes in concrete repair and restoration, so if your polished concrete floor needs touch-ups or refinishing after years of use, we can restore its smooth, glossy finish with no need for a complete overhaul.

Does polished concrete get cold?

Polished concrete can feel cooler to the touch than materials like carpet or wood, especially in colder weather. However, because concrete has a high thermal mass, it can retain heat well if exposed to sunlight or paired with radiant heating systems. In homes or commercial spaces with good insulation or in-floor heating, polished concrete can be quite comfortable even during Kentucky's colder months.

How does polished concrete compare in cost to other flooring options?

While the upfront cost of polished concrete may be comparable to or slightly higher than materials like tile or carpet, its long-term value makes it an economical choice. Polished concrete’s durability and low maintenance mean that you won’t have to worry about frequent repairs, replacements, or expensive upkeep. In commercial settings, the ease of cleaning and the extended lifespan provide significant cost savings over time.

Why choose Wolfcrete to do my polished concrete floors ?

Wolfcrete is the premier choice for polished concrete in Central Kentucky, because of our dedication to quality, craftsmanship, and customer satisfaction. With years of experience in the flooring industry, we understand the unique challenges of working with concrete in Central Kentucky's climate. Whether it's a residential garage, a commercial showroom, or an industrial warehouse, our team approaches every project with the same level of precision and care.

We take the time to assess the condition of your existing concrete, ensuring it’s properly prepared for polishing to guarantee a flawless and long-lasting finish. Using industry-leading equipment and materials, we deliver polished concrete floors that are not only beautiful but also built to withstand the test of time, even in high-traffic or heavy-use environments. Our transparent pricing means you’ll never face hidden fees or unnecessary upsells—just honest, reliable service.

From consultation to completion, we pride ourselves on clear communication and a seamless process. When you choose Wolfcrete, you’re not just getting a flooring contractor—you’re partnering with a team of professionals dedicated to transforming your space and exceeding your expectations.

Proudly Serving:

Shelbyville

Harrodsburg

Danville

Georgetown

Versailles